Quasicrystals are extremely poor electrical and thermal conductors. In fact the thermal conductivity of quasicrystals containing more than 70 atomic percent aluminum is two orders ofmagnitude below that of aluminum and roughly equivalent to that of zirconia, which is used as a refractory material. Quasicrystals are

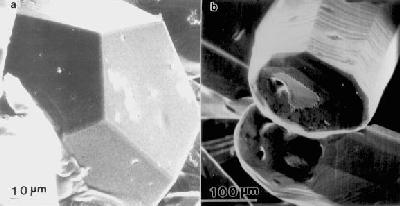

also exceptionally hard, and their surfaces have very low coefficients of friction, good wear resistance, and good oxidation and corrosion resistance. Also, depending on how they are prepared, quasicrystals can have coefficients of friction so low they are comparable to the coefficient of a diamond gliding over a diamond film.At first, there was an apparent obstacle to exploiting these properties: Bulk quasicrystalline materials are brittle at temperatures below a few hundred degrees Celsius. The solution to this problem was that quasicrystals made into coatings by the standard techniques of metallurgy, such as atomization and plasma spraying, retain the desirable properties, but not the brittleness, of the bulk material. So with these features, what can quasicrystals be used for? The first use lies in medicine, specifically medical tools. Put simply, there quasicrystals easily made into very strong and durable tools. Continuing on, titanium-based quasicrystals particularly titanium–zirconium–nickel, would be very useful for hydrogen storage. The reason being that hydrogen likes to sit in tetrahedral sites in transition metals. Quasicrystals because of their shape have huge amounts of tetrahedral sites. In addition, hydrogen is very specific about its bonding partners. It doesn’t work well with aluminum, but it works beautifully with titanium, zirconium, and the rare earths. So the titanium quasicrystals have the combination of a favorable chemistry and a favorable structural unit. Ken Kelton of Washington University in St. Louis found that titanium–zirconium–nickel quasicrystals can absorb nearly two hydrogen atoms per metal atom which is more hydrogen than is absorbed by related crystalline and amorphous materials. Moreover, it is more hydrogen than is absorbed by the hydrogen-storage materials currently in use, such as the lanthanum–nickel compounds in renewable batteries in laptop computers. “We can store almost double the weight percent of hydrogen that can be stored in lanthanum–nickel-5,” Kelton said. Some problems with is though is that Titanium–zirconium–nickel tends to form a surface oxide that can delay hydrogen loading. “This is not uncommon,” Kelton commented, “and we can get around it by gently milling the quasicrystal ribbons or by electrolytic loading.” He also noted that titanium-zirconium–nickel has so far been produced only by melt-spinning. Although the quasicrystal is stable, the reactivity of titanium has prevented it from being produced by the more versatile techniques used to make aluminum-based quasicrystals. The final potential use would be in the field of solar power. While quasicrystals lack exotic optical properties, their resistance to corrosion and abrasion might yield solar panels that do not require the "round the clock" maintenance needed by regular solar panels. The ideal solar-absorber material shows large absorption in the solar spectrum and is highly reflective at longer wavelengths. These characteristics basically give the effect of a window in a closed car. Sunlight comes in and is absorbed by the seats, but energy re-emitted as infrared radiation is trapped in the car by the windows. Thus, the car’s interior, becomes much hotter than its exterior. By similar means, solar-selective absorbers can reach temperatures as high as 500°C. Using quasicrystals, the closed-car effect can be achieved using a thin-film stack made up of a layer of quasicrystalline aluminum–copper–iron between two layers of the dielectric alumina deposited on a reflective metal had a solar absorptance of 90%.

While all these uses of the quasicrystal remain mostly untested, many different companies and people are cautiously optimistic of this technology. And for good reason, as these crystals have the to potential to change many things in the world of humans.

No comments:

Post a Comment